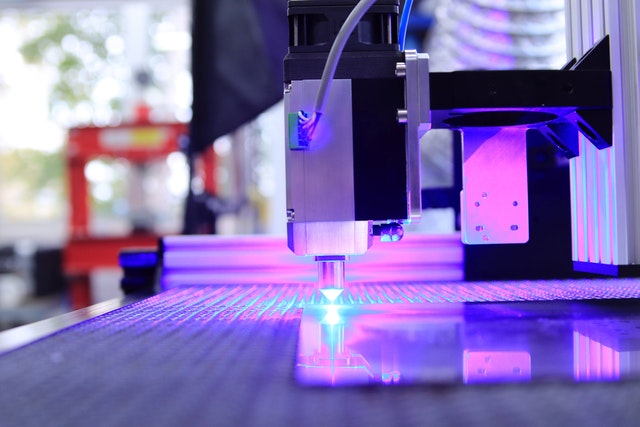

Professional contractors recognise how powerful a laser cutting machine can be for their operation. As client demands rise and excellence is expected, this is the type of investment that delivers residual benefits. This is a chance to look at 6 methods that point members in the right direction for their purchase.

1) Identify The Right Laser Model

What will shape the search for a laser cutting machine will be the type of contracting work that operators oversee day to day and week to week. Fabric designers will have very different needs to metal manufacturers for example. Thankfully these creations are able to handle a diverse range of material types, but it is beneficial to survey fibre laser, solid-state laser and CO2 laser as unique options in this environment, facilitating a superior cut for precise project needs.

2) User-Friendly Features

Unlike old utilities that would require manual labour processes, a modern laser cutting machine should be able to extend user-friendly features courtesy of a digital dashboard. This will include diverse material inclusion, different modes of cutting and shaping while the dashboard can be customised to meet the practices of any professional. These designs have to be integrated into an office or warehouse environment, so consider how user-friendly they happen to be and if they will be a good fit from a logistical standpoint.

3) Assess the Price Point

Seeking cutters that are able to deliver perfection to this degree won’t be cheap, but they won’t be pricing operators out of the market so long as they know what to buy and where to buy from. Reflect on the budgetary position and filter the selections according to their price point. This will give participants an opportunity to see what is financially viable and what can be sourced in the short-term before enjoying long-term gains.

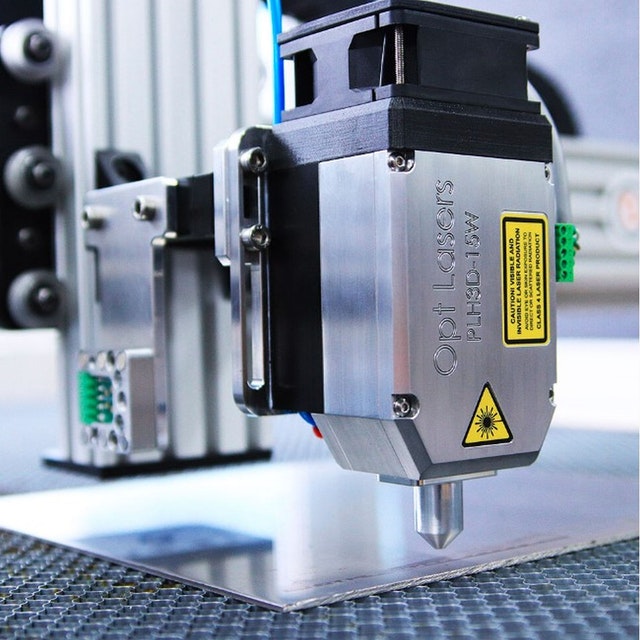

4) Cutting Precision & Industry Certification

Local participants want to know key two components when surveying their options with a laser cutting machine: is the product safe and will it deliver the kind of results that the best industry members can achieve? Industry certification is essential on this front because it guarantees that the supplier is manufacturing these tools to the highest possible standard before extending insurance and warranty policies. Then the precision comes into play with the top cutters delivering a margin of error inside 0.0005 inches.

5) Contractor Feedback & Product Ratings

Why attempt to buy a laser cutting machine blind? There are many contractors and industry specialists who require these models for their own commercial demands. They will each have their own opinion about what design works, what is most efficient, what saves on utility bills and what generates their best results for their brand. By taking note of 5-star ratings systems and comments published on online forums, constituents will generate a better picture about what is value for money in this market.

6) Having a Test Run

Contractors love to get hands-on with their tools. Even if they happen to be a hybrid between the old and the new courtesy of a laser cutting machine, there is no substitute for seeing how they can manipulate and alter a piece of material to suit the needs of the project. If there are participants out there who are curious to see how they are applied and how they work in real time, it is beneficial to seek a demonstration and have a test run.

Summary

Following these 6 key steps will help contractors to pick out a laser cutting machine that works for them. Each unit carries its own unique properties and selling points, but operators stake their reputation on these investments, so an extra degree of diligence and research will be beneficial.

Recent Comments